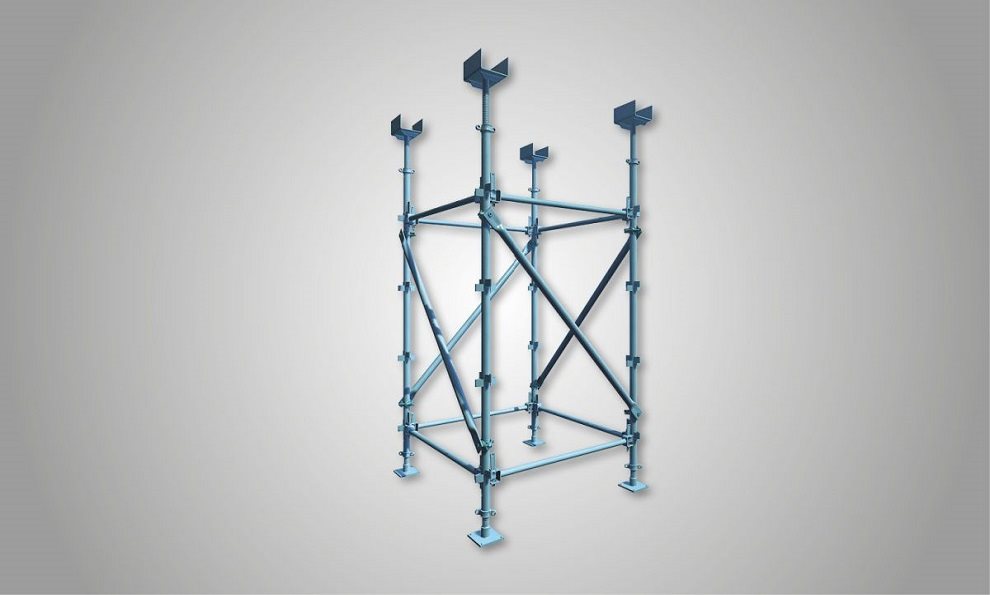

Our Kwikstage system

Our Kwikstage system provides one of the quickest ways to assemble steel falsework across any construction project, designed for simple assembly to maintain a safe and efficient work environment.

This propping system helps keep time and resources to a minimum, with basic components and a lightweight design to save on material and labour costs.

Spigot and Open Ended Standards

Our Kwikstage propping system is available to hire in two types of standards, a ‘Spigot’, allowing end to end connection, and the ‘Open Ended Standards’ for use with U-heads and Base Jacks at either end.

Each standard type can be connected quickly and easily with their unique V pressings at 495mm vertical centres along the tube.

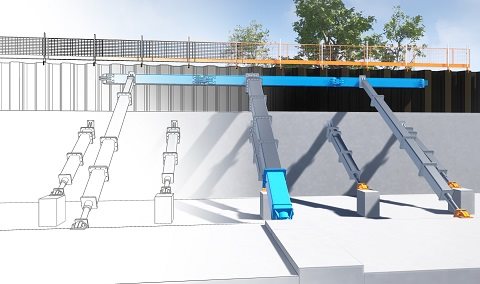

Applications

- Casting Concrete Soffits, Floors and Roofs

- Falsework

- Access or Shoring